As we all know, the DC system is mainly composed of a DC charging screen and a battery screen. Among them, the role of valve-regulated battery pack is particularly important. When the power grid fails, the battery pack will directly supply power to the load. It is the last pass of the DC system.

As a manager, how to manage these devices? How can I get the information I want? Such as: How is the battery status of the site now? Which sites will have their batteries replaced this year? Where is the battery maintenance level high? Which manufacturer's batteries are of good quality? Which power monitor is responsible for maintenance? Want to know this information anytime? Form a systematic report? These problems are the focus of our research and the problems to be solved by our program.

While valve-regulated batteries have outstanding advantages, they also have inherent deficiencies, such as:

● The capacity is difficult to test, water cannot be added, and high requirements for floating charging voltage and using ring system are required.

● After the battery is put into use, due to the design of the battery before leaving the factory, tooling equipment, quality control, and the setting of the float voltage during use, the use environment, temperature and other factors, the active material will fall off, deteriorate, and the positive grid will be corroded and vulcanized. Such phenomena will cause the entire battery group to lose capacity, uneven voltage, and backward single cells, which will bring great hidden dangers to safety production. When the power grid fails and needs battery power supply, once the battery does not discharge, it will cause a vicious accident. Therefore, the "Maintenance Regulations" requires a check capacity test on the battery, the purpose is to test the actual capacity of the battery pack, find out the backward battery, Eliminate hidden dangers.

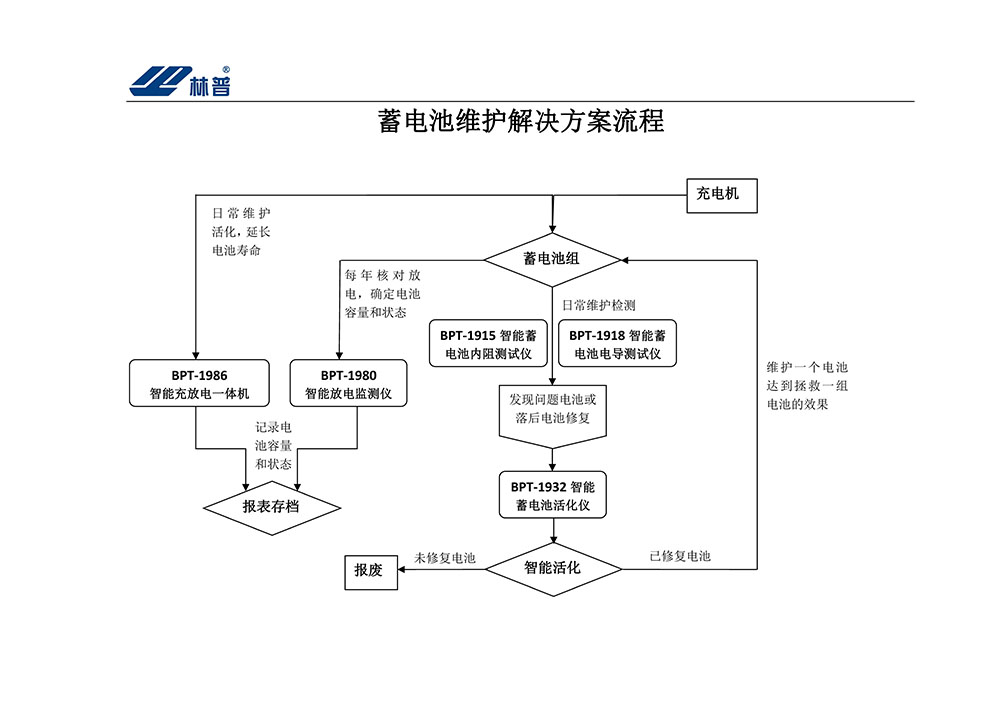

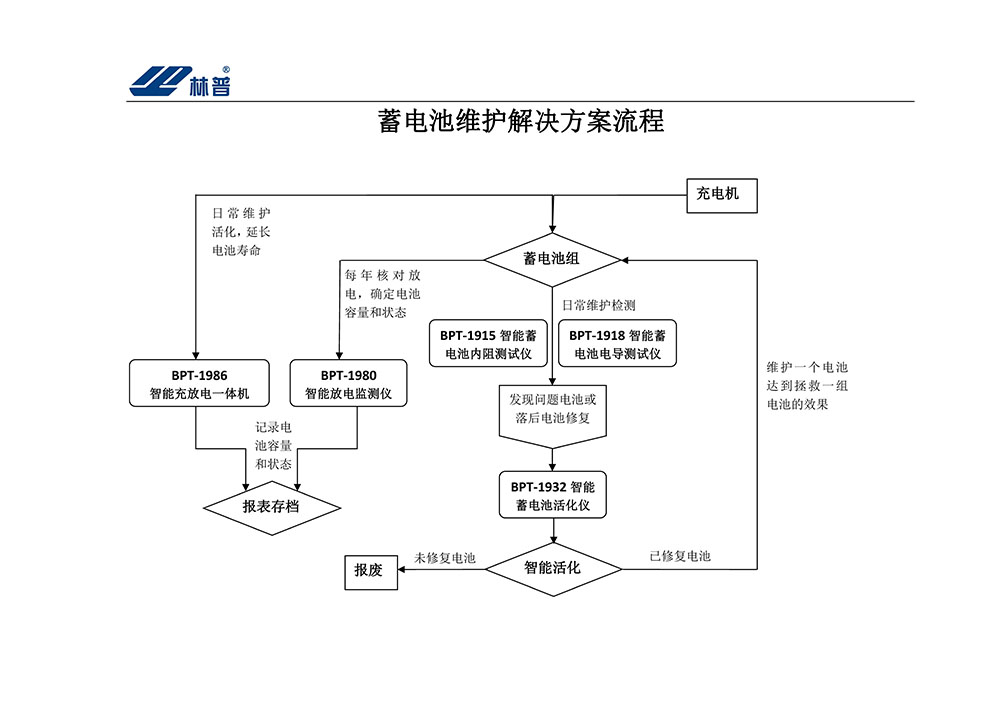

For this purpose, we take the following steps and means for battery maintenance in the actual work process:

● Perform routine maintenance and testing on batteries to find out unqualified or backward batteries. How to check? Just by experience? No, our "BPT-1915 Intelligent Battery Internal Resistance Tester" is your right-hand man for daily maintenance and testing. It can help you find outdated batteries, test the internal resistance and voltage of the battery, and preliminarily estimate the capacity of the battery. This solves the problem that the capacity is difficult to test After checking the outdated battery, you can effectively grasp the daily status of the battery.

● Are the outdated batteries detected must be unqualified or should be discarded? Not necessarily, in fact, many batteries in grey fabrics can be reused after repair. Due to the performance characteristics of the battery, the new and the old cannot be mixed, and the batteries of different brands and different batches cannot be mixed. In this way, activating one battery achieves the effect of saving a group of batteries. The implementer of this function is our "BPT-1932 Smart Battery Activator". It successfully solves the problem that the battery cannot be effectively repaired.

● After daily maintenance and activation, annual check and discharge will be carried out according to the regulations to determine the capacity and status of the battery very accurately. Use the "BPT-1980 intelligent discharge monitor" in our supporting products to complete the job.

● The above are all testing instruments in the process of regulation and routine maintenance. In addition, the charger has a great impact on the battery. Have you ever thought about the impact of the charger on the battery? If the ripple factor of the charger and the accuracy of voltage regulation and current regulation are far from the requirements, what will happen to the battery? It will dry up, swell or even burst. The general manufacturers have ignored this source, but we have not neglected. Our company has professional meters for chargers.

● Test to check the quality of the charger, so as to maintain the battery from the source of charging, which will be checked by "BPT-1960 DC Power Comprehensive Tester".

In addition, in accordance with the "Maintenance Regulations", the DC bus and other equipment should be regularly tested for insulation to analyze the insulation status of the equipment. Once a fault occurs, the "BPT-1835 DC System Grounding Fault Locator" will quickly locate the fault. Point, to achieve accurate search, save time and trouble.