1. Background and recommended scheme of JTG2182-2020 standard

The Ministry of Transport issued the "Highway Engineering Quality Inspection and Evaluation Standard Phase II Mechanical and Electrical Engineering" (JTG 2182-2020, referred to as "Standard"), as a mandatory standard for the highway engineering industry, which will be implemented from March 1, 2021. Highway Engineering Quality Inspection and Evaluation Standard Volume II Mechanical and Electrical Engineering (JTG F80/2-2004, referred to as the original "Standard") shall be abolished at the same time. In order to facilitate the understanding of the main contents of this revision and to effectively implement the work, the relevant revisions are now interpreted as follows:

(1) Background of revision

Since the implementation of the original "Standard" in 2004, it has played an important role in guiding the national highway mechanical and electrical engineering quality inspection, ensuring engineering quality and improving engineering technology. In recent years, a large number of new products, new technologies and new processes have been widely used in highway electromechanical engineering in my country, which has promoted the continuous development of highway electromechanical engineering, and put forward new requirements for engineering inspection technology and methods. In order to standardize the quality inspection and evaluation of highway mechanical and electrical engineering, unify testing methods and technical requirements, and solve the shortcomings in the original "Standard", the Ministry of Transport organized and completed the revision of the "Standard".

(2) Major revisions

The "Standard" has carried out a lot of theoretical research and experimental verification on the basis of fully absorbing the latest research results of highway mechanical and electrical engineering testing and testing in the transportation industry and the experience in the implementation and use of the original "Standard". Major revisions include:

1. In view of the new equipment that has appeared in domestic highway electromechanical engineering in recent years, a number of traffic situation investigation facilities, video traffic incident detection systems, wavelength division multiplexing (WDM) optical fiber transmission systems, overrun detection systems and electric vehicle charging systems have been added. In the testing content of the sub-projects, the communication facilities sub-project adds IP network system, wavelength division multiplexing (WDM) optical fiber transmission system and fixed telephone switching system. The communication pipeline and optical and cable line sub-projects are adjusted to two sub-projects: communication pipeline project and communication optical cable and cable line project, and the wireless mobile communication system and emergency telephone system are deleted.

2. In order to make up for the shortcomings in the existing inspection work and improve the quality of the project, the inspection items of the geomagnetic vehicle detector have been added to the vehicle detector; the inspection items of the audio cable have been added to the communication optical and cable line engineering; The inspection items of UPS and EPS power supply have been added to the low-voltage power distribution equipment in the center (station); the inspection items of electric heat tracing and fire shutters in the cross passage of vehicles have been added to the fire protection facilities; and the equipment and software of the tunnel management station have been added. Check items for contingency plans.

3. In order to ensure the construction quality of highway mechanical and electrical engineering, the technical requirements for inspection items such as shared grounding resistance, average loss of multimode optical fiber connectors, and verticality of light poles have been improved.

4. Referring to the relevant content in the published "Highway Engineering Quality Inspection and Evaluation Standard Volume 1 Civil Engineering" (JTG F80/1-2017), the qualification rate method is used to evaluate the quality of mechanical and electrical engineering, which is more rigid than the old scoring method strict. Since the equipment of electromechanical engineering is manufactured in factories, the quality requirements are higher than that of civil engineering. Therefore, in order to ensure the quality of the project, it is stipulated that the pass rate of key items of electromechanical engineering should be 100%, and the pass rate of general projects should not be less than 90%. %.

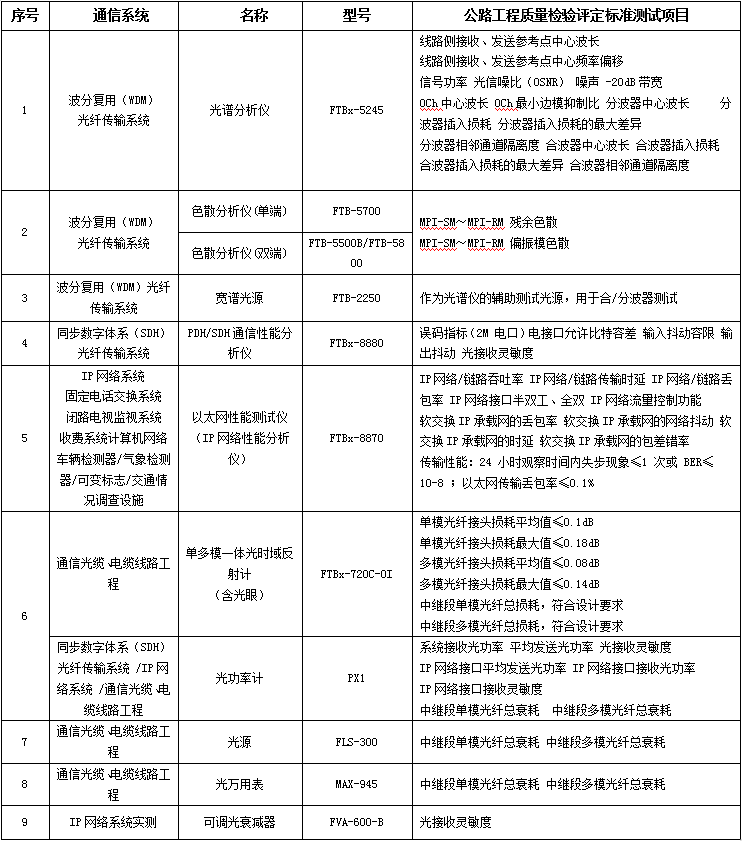

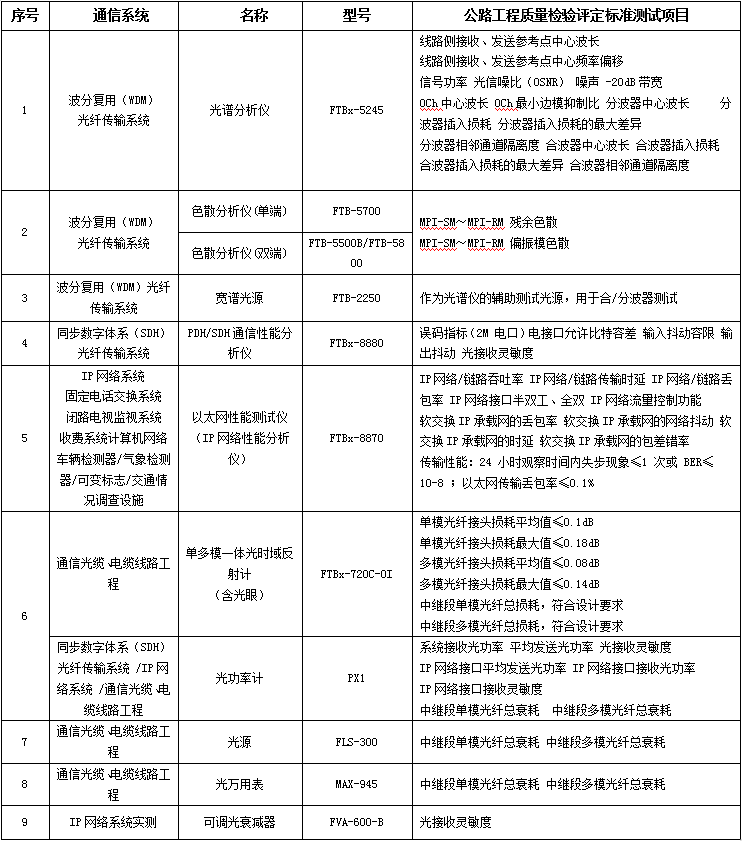

2. About JTG2182-2020 Communication Test Plan (EXFO) for Electromechanical Engineering

3. Advantages of testing solutions

2.1 One-click test and automatic calculation of wavelength division multiplexer (WDM) demultiplexer/multiplexer

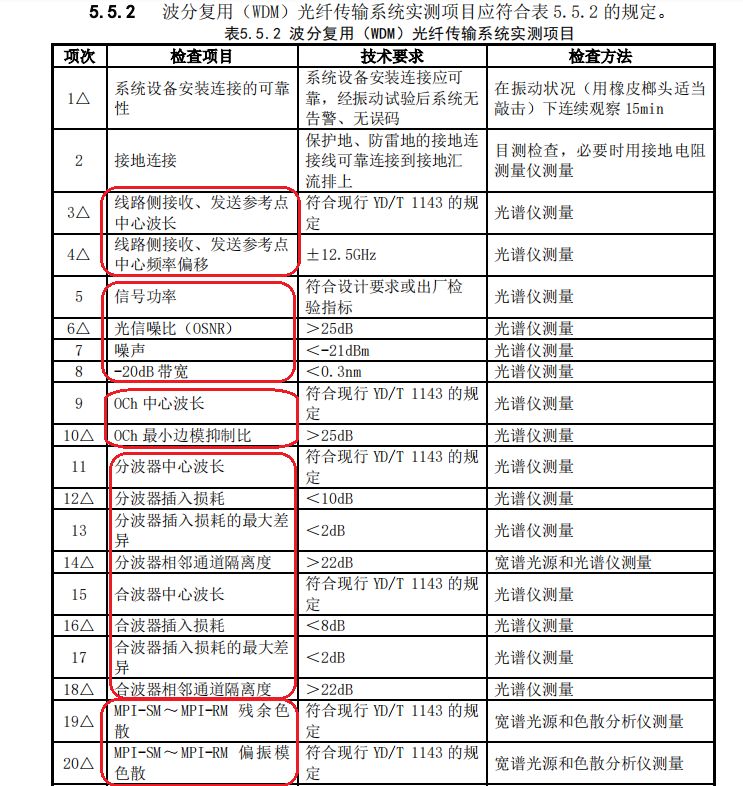

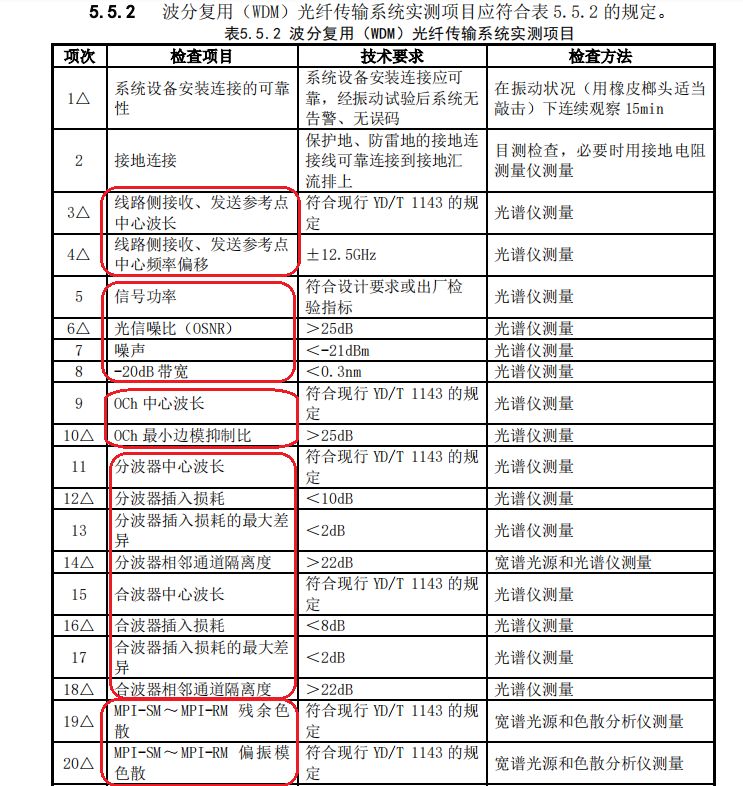

The above chart is the test item of JTG 2182-2020 highway engineering quality inspection and evaluation standard wavelength division multiplexing (WDM) optical fiber transmission system spectrometer analyzer, which can be divided into line test and demultiplexer/multiplexer test, all wavelength division multiplexing (WDM) WDM) system testing can be classified into these two categories.

Items 3 to 10 in the chart are line interface tests, which are test items on the receiving interface and transmitting interface of the device.

Items 11 to 18 in the chart are the demultiplexer/multiplexer test. In the wavelength division multiplexing (WDM) system, the demultiplexer/multiplexer plays an important role. It combines the two waves. Together or separately, if the performance of the demultiplexer/multiplexer is not good, it may cause mutual interference between the channel and the channel. In the wavelength division multiplexing (WDM) system, the demultiplexer/multiplexer test item The proportion is the largest, and it is also the most important indicator of the wavelength division multiplexing (WDM) wavelength division system.

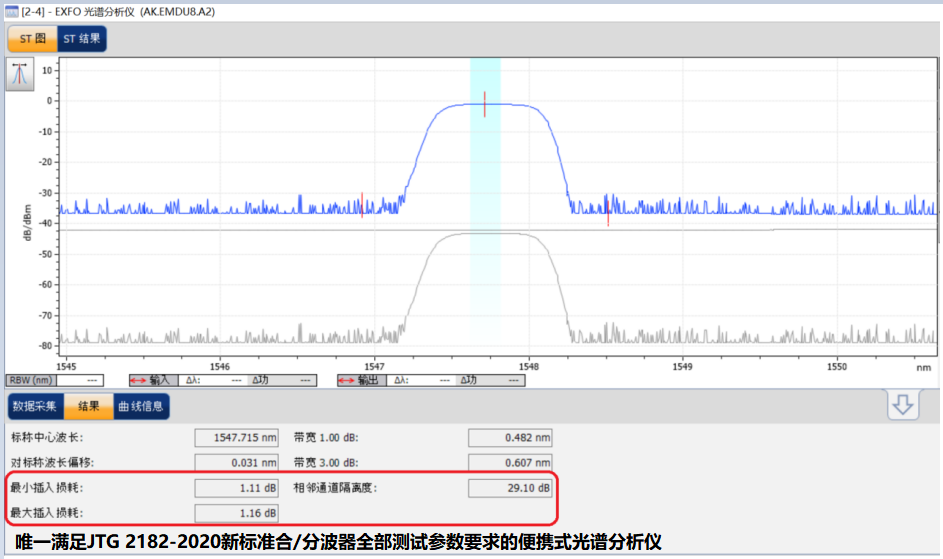

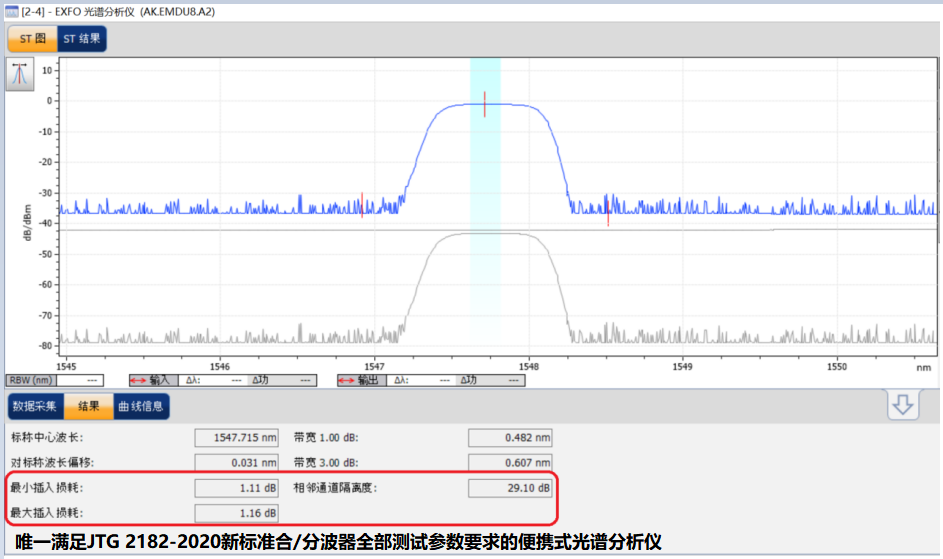

The advantage of EXFO's spectrum analyzer is that the ST measurement mode can be selected for items 11 to 18 in the chart to automatically perform the test of the demultiplexer/multiplexer, and automatically obtain the required measurement results including the isolation of adjacent channels. The process does not require manual intervention, and is completely automatically calculated by professional instruments and obtains accurate results. However, other spectrum analyzers on the market do not have a corresponding test mode. The test of the isolation of adjacent channels can only rely on manual measurement, which requires manual recording and manual calculation to know the result. In addition to this test function, EXFO spectrometers are superior to other brands of spectrometers in various indicators. Therefore, EXFO spectrometers occupy more than 90% of the industry in the field of communication operators and road traffic detection.

EXFO Instrument Test Interface

2.2 High-efficiency single-ended dispersion test method

Dispersion is a relatively complex optical physics concept, and it is divided into two types, chromatic dispersion CD and polarization mode dispersion PMD. The 19th item of the residual dispersion in the chart is the chromatic dispersion in the system after passing through the dispersion compensation module, so the residual dispersion is essentially the chromatic dispersion; the 20th item in the chart is the polarization mode dispersion.

There are also two methods for measuring dispersion, the single-ended method and the double-ended method. The single-ended dispersion tester only needs one person to use the meter at one end of the optical cable to be tested to test the chromatic dispersion CD and polarization mode dispersion PMD; the so-called double-ended method requires two groups of people, one group of people at one end of the optical cable , using the light source, and the other group at the other end of the optical cable, using the dispersion analyzer, the two groups communicate with each other, and the light source and the dispersion analyzer cooperate with each other.

The obvious first advantage of the single-ended test method is to save labor, improve efficiency and reduce costs.

Secondly, highway optical cables are generally buried in the ground, but if they pass through a long-span bridge, the polarization mode dispersion of the optical cable will change with the shaking of the bridge, and the PMD value will change rapidly. According to the traditional test method (fixed analysis method), Untestable conclusions are usually reached after a long wait. On the other hand, the overhead mode of the EXFO single-ended dispersion analyzer can quickly lock on to the PMD and converge quickly for accurate testing.

EXFO's single-ended dispersion analyzer is currently the only test tool that supports chromatic dispersion (residual dispersion) and polarization mode dispersion for overhead optical cables or long-span bridge optical cables.